PSI后卫密封垫片

| 订货号: | MM-80667-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

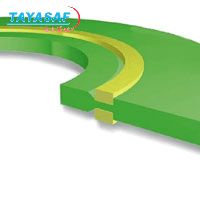

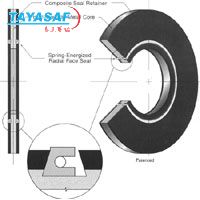

PSI LineBacker® Sealing Gaskets utilize a patented rectangular sealing element, referred to as a “quad” ring, in combination with a unique groove design to effectively seal and isolate flanges of all types. This unique design provides elastic memory. Materials such as polyimide, TFE (Teflon) and vinyl may be used as sealing elements, which dramatically increases the options available for matching gasket materials to service and environmental conditions. A much broader range of retainer material/seal element combinations may therefore be used for excellent temperature and chemical range compatibility.

Features of the LineBacker® Sealing Gasket:

Eliminates flange leaks.

Guards against blowouts.

Protects against fire and hostile environments.

Usable with any type of flange.

Matches gasket materials to service conditions.

Lowest possible clamp and compressive load.

Increases gasket life.

Insulating version is both a positive seal and a superior insulator.

Available in all standard ANSI and API flange sizes from 1/2” and above.

Available in custom or odd sizes and shapes.

Available in pressure ratings for all ANSI and API rated flanges.\

For pressures from hard vacuum to 50,000 psi and higher.

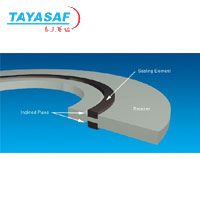

How LineBacker Works

Before Tightening

The flange faces come into contact with the sealing elements, which extend slightly above the surface of the retainer. As the flange is tightened the sealing elements are compressed and move sideways into the inclined portion of the groove, developing a high unit pressure against the flange faces.,

Before Tightening

The flange faces come into contact with the sealing elements, which extend slightly above the surface of the retainer. As the flange is tightened the sealing elements are compressed and move sideways into the inclined portion of the groove, developing a high unit pressure against the flange faces.,

After Tightening

The flange faces have come into firm contact with the retainer, thus encapsulating the sealing elements within grooves. At the same time, the unique LineBacker seal configuration provides elastic memory for elastomers not normally associated with this characteristic - resulting in a simple flat gasket with extremely high loading and self energizing characteristics without adverse cold flow problems.,

The flange faces have come into firm contact with the retainer, thus encapsulating the sealing elements within grooves. At the same time, the unique LineBacker seal configuration provides elastic memory for elastomers not normally associated with this characteristic - resulting in a simple flat gasket with extremely high loading and self energizing characteristics without adverse cold flow problems.,

Wide Choice of Materials

LineBacker® gaskets are available in a wide variety of retainer and sealing element combinations for matching gaskets to service and environmental conditions. This greater variety of materials also provides excellent temperature and chemical range compatibility.

|

Metal Retainer Materials |

Insulating Retainer Materials |

Sealing Elements |

|

Aluminum Brass Carpenter 20 Carbon Steel Cast Iron Clad Steel Materials Copper Ductile Iron Hastelloy B Hastelloy C Hastelloy X Inconel X Monel Nickel 200 Soft Iron Stainless Steel Tantalum Tin Titanium Vanadium |

Ceramic Epoxy Glass Glass Lucite Melamine Phenolic Polyester Glass Polyethylene Polyphenol Ether Pyrox Silicone Glass Vinyl |

Buna-N (Nitrile)

Buna-S Butyl EPDM Hypolon Kel-F Natural Rubbers Neoprene Nylon Polyimide Polyurethane Silicone Rubber Teflon* Vinyl Viton* *DuPont |

Suggested Sealing Gasket Material Compatibility

|

Medium |

Retainer |

Seal |

Temperature Range °F |

Temperature Range °C |

|

Acetone |

Phenolic |

Nitrile |

+32 to +80 |

0 to +27 |

|

Air |

G-10 |

Nitrile |

-65 to +225 |

-54 to +107 |

|

Ammonia Dry |

G-10 |

Teflon |

-65 to +220 |

-54 to +104 |

|

Ammonia (Wet)*** |

G-10 |

Teflon |

+32 to +100 |

0 to +38 |

|

Bleach |

G-10 |

Teflon |

+32 to +80 |

0 to +27 |

|

Butylene (Butidiene) |

G-10 |

Teflon |

+32 to +100 |

0 to +38 |

|

Carbon Dioxide |

G-10 |

Nitrile |

+32 to +150 |

0 to +66 |

|

Caustic Soda (NaOH) |

G10 |

Teflon |

-65 to +225 |

-54 to +107 |

|

Cryogenic |

G-10 |

Teflon |

-300 to +280 |

-184 to +138 |

|

Ethanol |

G-10 |

Nitrile |

+32 to +100 |

0 to +38 |

|

Ethylene (Ethene) |

G-10 |

Teflon |

+32 to +80 |

0 to +27 |

|

Fuel Oil |

G-10 |

Viton |

-20 to +280 |

-29 to +138 |

|

Gas, Natural |

Phenolic |

Nitrile |

-65 to +220 |

-54 to +104 |

|

Gas, Sour |

Phenolic |

Viton |

-20 to +220 |

-29 to +104 |

|

Gasoline |

G-10 |

Teflon |

-65 to +225 |

54 to +107 |

|

Hydrogen |

G-10 |

Nitrile |

-65 to +250 |

-54 to +121 |

|

Jet Fuel |

G-10 |

Viton |

-20 to +225 |

-29 to +107 |

|

LNG |

G-11 |

Teflon |

-300 to +100 |

-184 to +38 |

|

Mercaptan |

G-10 |

Teflon |

-20 to +80 |

-29 to +27 |

|

Methanol |

G-10 |

Teflon |

+32 to +100 |

0 to +38 |

|

MTBE |

G-10 |

Special Nitrile |

+32 to +80 |

0 to +27 |

|

Nitrogen |

Phenolic |

Nitrile |

-65 to +220 |

-54 to +104 |

|

Oil, Crude |

G-10 |

Viton |

-20 to +280 |

-29 to +138 |

|

Oxygen** |

G-10 |

Teflon |

-65 to +250 |

-54 to +121 |

|

Pentane |

G-10 |

Teflon |

+32 to +80 |

0 to +27 |

|

Propane |

G-10 |

Nitrile or Teflon |

+32 to +80 |

0 to +27 |

|

Propylene |

G-10 |

Viton |

+32 to +80 |

0 to +27 |

|

Sewage |

G-10 |

Viton |

-20 to +280 |

-29 to +138 |

|

Spent Liquor |

G-10 |

Teflon |

+32 to +100 |

0 to +38 |

|

Steam* |

G-7* |

Teflon |

to +450 |

To +232 |

|

Steam |

G-3 |

Teflon |

to +392 |

To +200 |

|

Steam* |

Yellow Jacket |

No Seal |

to +450* or +392 |

to +268* or +200 |

|

Styrene |

G-10 |

Teflon |

+32 to +80 |

0 to +27 |

|

Sulphur (Molten) |

G-10 |

Teflon |

+32 to +280 |

0 to +138 |

|

Toluene |

G-10 |

Viton or Teflon |

+32 to +150 |

0 to +66 |

|

Water (Hot) |

G-10 |

Nitrile |

+175 to +250 |

+79 to +121 |

|

Water (Potable) |

G-10 |

Nitrile |

+32 to +250 |

0 to +121 |

|

Water (Sea) |

G-10 |

Nitrile |

+32 to +250 |

0 to +121 |

|

White Liquor |

G-10 |

Teflon |

+80 to +280 |

+27 to +13 |

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

绝缘法兰订货号:MM-80658-00

绝缘法兰订货号:MM-80658-00 新型绝缘法兰订货号:MM-80659-00

新型绝缘法兰订货号:MM-80659-00 PSI绝缘法兰订货号:MM-80667-00

PSI绝缘法兰订货号:MM-80667-00 PSI250及251密封垫片订货号:MM-80668-00

PSI250及251密封垫片订货号:MM-80668-00 PSI隔离密封垫片订货号:MM-80662-00

PSI隔离密封垫片订货号:MM-80662-00 PSI-GasketSeal密封垫片订货号:MM-80670-00

PSI-GasketSeal密封垫片订货号:MM-80670-00 PSI-FlangeMate密封垫片订货号:MM-80670-00

PSI-FlangeMate密封垫片订货号:MM-80670-00 PSI传统密封垫片订货号:MM-80671-00

PSI传统密封垫片订货号:MM-80671-00 PSI的法兰分离试剂盒订货号:MM-49639-00

PSI的法兰分离试剂盒订货号:MM-49639-00 PSI隔离套和垫圈订货号:MM-80664-00

PSI隔离套和垫圈订货号:MM-80664-00 PSI-LineSeal临界密封用垫片订货号:MM-80666-00

PSI-LineSeal临界密封用垫片订货号:MM-80666-00 Pikotek VCS法兰垫片订货号:MM-80672-00

Pikotek VCS法兰垫片订货号:MM-80672-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-80667-00 | PSI后卫密封垫片 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

您最近浏览的商品

美国MI

美国MI