Description

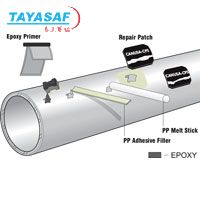

Syntho-Subsea™ Epoxy is ideal for patching, sealing and coating a wide variety of materials including steel, concrete, wood, aluminum and fiberglass. Syntho-Subsea™ is a two-component, Kevlar reinforced, epoxy mastic coating for sealing and repairing leaks in pipelines.

Typical Applications

Seal leaks in SubSea pipelines, joints and fittings.

Fill in anomalies, voids and surface imperfections on pipelines .

Protective corrosion coating in splash zone and tidal prone areas.

Adhesive, protective coating on wet surfaces or under water.

Pipeline anomaly reinforcement and remediation

Benefits

Easy to use as an adhesive or coating on both wet surfaces and under water

Excellent adhesion

Resistant to high pressures

Resistant to high and low temperature extremes

Outstanding resistance to petroleum products and chemicals

Physical Properties

|

Color, Resin

Color, Curing Agent

Coverage, 30 mils

Pot Life

Compression Strength

Tensile Strength

Flexural Modulus

Flexible Strength

Solids Content

Maximum Use Temperature

Cure Time |

Blue

Yellow

5 sq. ft / 16oz kit

60 minutes at 77°F (25°C)

7,380 psi

7,600 psi

13,600 psi

13,000 psi

100%

200°F (93° C)

24hrs at 75°F (26°C) |

Preparation & Application

1. , Clean and roughen: A clean surface, free of grease, loose rust and scale is required. Remove any grease, oil and petroleum products with a solvent wiping. After cleaning and degreasing, remove any loose scale and roughen surface by mechanical means.

2., Mixing notes: Do not mix Syntho-Subsea™ underwater. For underwater applications mix on the boat then transfer to the repair site. A pair of disposable gloves and a plastic putty knife are supplied with each kit for mixing and applying.

3., Mix: Add all of the curing agent, (part B) into the resin container (part A), scrape sides and bottom of the container. Mix the resin and curing agent together until a smooth, uniform and streak free mixture is obtained.

4., Application: Apply with a putty knife, spatula or trowel. For underwater applications, it is important to apply sufficient pressure to displace the water on the surface. Spread carefully while working the material into indentations to avoid trapped air or water pockets, prior to building up to the desired thickness. A coating thickness of 60 mils or more is achievable without running or sagging, however for most applications a coating of approximately 30-60 mils is normally sufficient.

5., Notes:

• It is important to feather the edges of Syntho-SubSea for a water tight seal.

• If multiple coats are to be used, roughen the surface in-between coats.

• Available from stock in

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比