Description

Model "R" End Seals are available in five (5) different sizes to accommodate a wide range of carrier/casing diameter combinations. A unique "cone" design, with molded-in dimensions, is easily cut to size for a correct fit on the carrier pipe. Stainless steel bands are included for clamping the Model "R" end seal to both casing and carrier pipes.

Manufactured from 1/8" (3.18 mm) thick high-quality EPDM rubber, Model "R" end seals are extremely robust, resistant to a wide variety of environmental conditions and may be used to prevent the ingress of moisture and soil into the annular space between carrier and casing pipes.

Features & Benefits

Low storage costs, only five end seal sizes to accommodate casings from 4" to 24" in diameter with all applicable carrier pipe sizes.

Quick and Easy Installation.

Manufactured from 1/8" (3.18mm) thick high quality EPDM rubber.

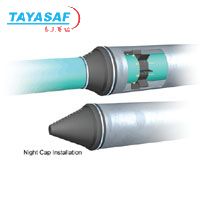

Casing night cap prevents entry of debris and animals during install. , Sizes are clearly printed on sleeved to simplify cutting to the correct size.

Designed To Last for the Life of the Piping System

Stainless steeel bands for clamping both ends of end seal provided.

May be used for new installations.

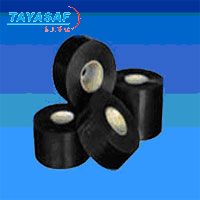

Material Specifications

|

Material |

EPDM 60 |

|

Thickness |

1/8" (3.18 mm) |

|

Color |

Black |

|

Temperature |

250°F (121°C) |

|

Hardware |

304 stainless steel bands with work screws |

Note: , Standard casing end seals are designed for below grade use. For above grade applications, please contact Corrosion Control Products Company.

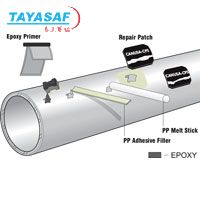

Installation

Simply cut the seals at the closed end to the measured external diameter of the carrier pipe. (Note: the printed sizes are marked on the end seals.) Push the end seal over the outside of the casing pipe and the carrier pipe and fasten with the included stainless steel bands.

Prepare outside surfaces by removing dirt from casing and carrier pipe.

After carrier pipe is inserted into casing, slide small end of end seal over the carrier pipe with stainless steel banding clamp. Large end should face casing.

Position large end of end seal over the casing pipe.

Position banding clamp approximately 1” from the end of the casing pipe and then tighten onto the end seal.

Fold end seal in an “S” shape so it will extend into the casing.

Position banding clamp approximately 1” from the end of the end seal on the carrier pipe and then tighten. (Make sure the end seal is folded into the casing, to relieve stress during backfilling and allow for expansion and contraction movement.)

Repeat steps 1, & 3 - 6 on other end of casing.

Typical Specification

Model "R" end seals shall be manufactured from a minimum 1/8” thick synthetic rubber. Banding clamps shall be 304 stainless steel with worm screws. End Seals shall be PSI Model "R" as manufactured by PSI-Pipeline Seal and Insulator, Inc. A copy of current ISO 9001:2000 registration shall be provided with material submittal.

How to Order

There are five Models to choose from. Select the appropriate end seal for your casing pipe O.D. (colored bars below), then verify that your carrier pipe O.D. is within the cone's diameter range.

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比