Description

|

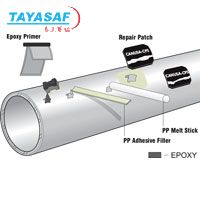

PSI Model C Coated Casing Isolators are used to electrically separate carrier pipes from the casings through which they pass.

PSI polyvinyl chloride coated (PVC) casing isolators are often selected due to their strength and excellent corrosion resistance. An extremely tough and durable heat-fused PVC coating is offered on steel casing isolators 4" and larger, with 12" wide bands. The cold-formed steel casing isolator band, complete with runner studs installed, is vapor degreased, primed, heated and fusion coated with plastic, providing a minimum .010" (0.254 mm) thick coating over the entire band and runner studs. A post-cured cycle strengthens the bond and provides an even more uniform coating. Polyvinyl chloride is available as standard. Other heat fused plastic coatings are also available for custom orders and applications.

Runners are attached with 3/8" diameter studs, which are fusion-welded to the band before it is PVC coated. They are recessed far below the wearing surface of the runner. After the runner is anchored to the band, the stud counter-bore is filled to assure a water-tight seal for the stud and the lock fastener. |

|

Glass reinforced runners offer coefficient of friction = 0.1 to 0.6.

Glass reinforced polymer runners offer 18,000 PSI (1,265 kg/cm²) compressive strength.

Riser height may be specified for specific positioning of carrier pipe within casing.

High-temperature T.P.E. inner liner protects pipe and/or coating.

Liner offers excellent corrosion resistance and back-up insulation.

May be used for long pulls and/or heavy pipe installations.

Designed to last for the life of the piping system.

Deeply embossed flanges offer added strength during tightening of flange bolts.

Eliminates need for blown sand or pea gravel.

Available with 12" bands.

Available with 2" wide runners.

Material Specifications for Coated Casing Spacers

|

Band |

14 Gauge (0.074"[1.88mm]) hot-rolled and pickled mild steel. Flanges of the spacer are deep embossed, and the corners are chamfered. |

|

Configurations |

4" (101.6 mm) through 36" (914mm) = 2-piece

36" (914 mm) through 48" (1,219mm) = 3-piece

48" (1219 mm) and over = Consult Factory |

|

Finish |

Type: Fusion Bonded PVC Coating |

|

Hardness: Durometer - shore A2 (10 sec) (ASTM D1706-61T): 80 |

|

Maximum Operating Temperature (constant): 150°F (65°C) |

|

Aging Properties: Excellent |

|

Electrical Properties (ASTM D149-61) (short time 0.010"): 1380 V/mil |

|

Environmental Resistance:

Salt Spray (ASTM B117): Excellent

Acids: Good

Alkalies: Good |

|

Liner |

Material: T.P.E. |

|

Thickness: 0.118" (3.0 mm) min. |

|

Hardness: Durometer "A" 73 |

|

Dielectric Strength, 1/8" (3.18mm) Surge Test: 60,000 V min.

Dielectric Strength, Step-by-Step Test: 58,000 V min. |

|

Water Absorption: 1% max. |

|

Risers |

10 Gauge (0.135mm) steel MIG welded to band. |

|

Runner Types |

2" (51 mm) wide glass-reinforced polymer runners

4" (101.6mm) through 12" (305 mm) = 2 top & 2 bottom

14" (356mm) through 36" (914 mm) = 2 top & 4 bottom |

|

Runner Specifications |

Tensile Strength, (ASTM D638): 17,600 psi (1,237kg/cm²)

Flexural Strength, (ASTM D790): 25,300 psi (1,779kg/cm²)

Compression Strength, (ASTM D648): 18,000 psi (1,266kg/cm²)

(10% Deformation)

Deflection Temp. @ 264 psi, (ASTM D648): 405°F (205°C) |

|

Studs, Nuts & Washers |

Studs = 5/16" - 18 x 2-1/2" plated

Hex Nuts = 5/16"

Washers = 5/16" SAE 2330 |

|

Band |

12" (305 mm) Band = 8 studs, 16 nuts and washers |

|

Warranty |

Products are warranted against failure caused by manufacturing defects for a period |

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比