Description

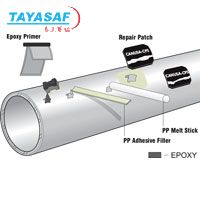

PIPE-GUARD Rock Shield III is a flexible padding designed especially for the protection of the corrosion coating on pipelines when rocky backfill is encountered.

Advantages

PIPE-GUARD Rock Shield III provides the padding required for pipe coatings without the concern of blocking out cathodic protection.

PIPE-GUARD Rock Shield III has a flat interior surface that will not mar soft coatings.

PIPE-GUARD Rock Shield III saves money at every step of the operation through its convenience and ease of application.

PIPE-GUARD Rock Shield III’s flexibility, even at colder temperatures, allows for quick and easy application lengthwise or cigarette wrap using tape or strapping products.

PIPE-GUARD Rock Shield III helps protect the coating from the abrasive movement of the pipe in the ground over long periods.

Availability

PIPE-GUARD Rock Shield III is readily available. It is supplied in a standard roll size of 5’ wide x 100’ roll long weighing 77 lbs.

Benefits

Absorbs impact of uneven backfill

Protects pipe coating from jagged rocks in trench.

Helps prevent abrasions from pipe movement underground.

Protects pipe from future excavations.

Material is lightweight and easy to handle.

Product Data

|

Parameter |

English |

Metric |

Test Method |

|

Thickness, minimum

Nominal |

0.145"

0.160" |

3.68 mm

4.0 mm |

ASTM D4801 |

|

Weight, minimum

Nominal |

0.144 lbs/sq ft

0.155 lbs/sq ft |

800 kg/m2

750 kg/m2 |

|

|

Tensile Strength, minimum |

2757 lbs/sq in |

19.0 N/mm2 |

ASTM D1682

modified |

|

Toughness (weak strand)

Breakload x elongation, min |

7 |

7 |

|

|

Compressive Strength, nominal |

200 lbs/sq in |

140,000 kg/m2 |

ASTM D1621

modified |

|

Impact Resistance, limestone drop |

Pass |

Pass |

ASTM G13 |

|

Impact Resistance |

Rockshield protected |

ASTM G14(1) |

|

Type of Coating - no holiday at: |

No holiday at: |

No holiday at: |

|

|

Fusion Bonded Epoxy |

22.9" |

58.2 cm |

|

|

Polyethylene Tape |

21.9" |

55.6 cm |

|

|

Coal Tar Enamel |

42.0" (2) |

106 cm |

|

|

Specific Gravity, minimum

Maximum |

35 lbs/cu ft

43 lbs/cu ft |

0.56 g/cm3

0.69 g/cm3 |

|

|

Strand Angle, minimum

Maximum |

80º

90º |

80º

90º |

|

|

Strand Count, minimum

Maximum |

3.1/inch

3.7/inch |

1.22/cm

1.45/cm |

|

|

Resin Density, minimum |

58.6 lbs/cu ft |

0.94 g/cm3 |

ASTM D1505 |

|

Resin Melt Index, minimum |

0.22 lbs/

10 minutes |

1.00 g/

10 minutes |

ASTM 1238A |

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比