Composition

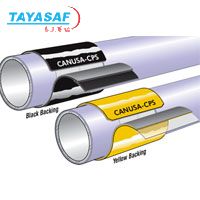

Tapecoat 20 consists of a specially formulated pliable coal tar coating completely saturated into and bonded to both sides of a high tensile strength fabric. In addition, it has a polyester film adhering to the coating which facilitates unwinding of the roll and acts as an outer wrap, providing additional mechanical strength against backfill and soil stress.

Technical Data

|

Softening point |

-170°F ± 5°F (-77°C ± 3°C) |

|

Penetration |

0.3 to 0.8 mm at 77°F (25°C) |

|

Thickness |

58 ±2 mils (1.47 ± 0.05 mm) |

|

ASTM G-8 C.D. |

250 oz / inch width (2.79 kg/cm width) |

|

Elongation |

Passes |

|

Oil & hydrocarbon resistance |

Excellent |

|

Specs & standards |

Meets Federal Spec HHT 30a and AWWA Standard C203 |

|

Compatibility |

Coal tar, asphalt, polyethylene, polypropylene, FBE and other factory coatings |

|

Tests |

ASTM E28, ASTM D5, ASTM G8, ASTM G20 |

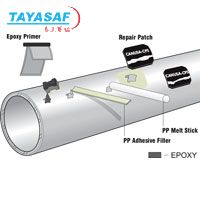

Application

Equipment: A torch with wide mouth burner is recommended.

Surface Preparation: Surface must be clean and dry. Wire brush to remove any loose rust and scale, dust or dirt. Oil, grease and all other residue are to be removed from pipe surface. Use torch to warm the surface and remove moisture prior to priming.

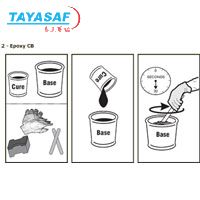

Primer Application:

TC Omniprime is the compatible primer for use with Tapecoat 20. Apply primer to the prepared surface by brush or roller at the rate of approximately 300 square feet per gallon. TC Omniprime should be applied 4" beyond the area to be wrapped with tape. Let primer dry before applying Tapecoat 20. TC Omniprime can also be used on stainless steel.

Tape Application: There are two recommended methods for applying Tapecoat 20 to a properly prepared and primed surface.

Spiral Wrap: Flash flame of torch onto the side of the coating without the polyester film (outside of roll) until a smooth and glossy finish is obtained. Apply properly heated coating with tension to the surface of the pipe. Alternately heat and spiral wrap in a single thickness with a continuous 1/4" to 1" overlap of tape.

Cigarette Wrap: Precut strips of Tapecoat 20 to a length equal to the circumference of the pipe plus a minimum of 3" for overlap. Follow general tape application instructions described above.

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比