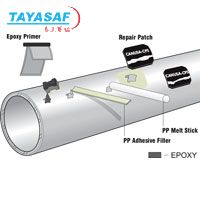

System Description

Polyken 2036 is a primary anti-corrosion joint wrap tape designed for use in field coating applications. 2036 joint wrap tape provides superior bond strength to primed steel, has a continuous operating service temperature up to 200°F, and has excellent conformability when applied to pipe.

Polyken 2036 joint wrap tape consists of a special polyethylene with very high resistance to environmental stress cracking combined with an engineered butyl alloy based adhesive, which cures when the coated pipeline begins operating at its elevated temperature. This curing gives superior resistance to shear and soil stress. It has proven in-ground success against chemical and electrolytic corrosion due to the combined effects of the polyethylene and butyl adhesive components.

Polyken 2036 is a high temperature coating which will have satisfactory performance up to 200°F continuous operating temperature. This product should be used with a special high shear Polyken primer, such as 2019 or 2027.

Product Features & Benefits

Proven Performance: Polyken 2036 is part of the total Polyken product coating system, which is used on a world-wide basis under all types of pipeline construction specifications., Integral Bond: Polyken 2036 will bond to the specially primed steel surface providing for long-term, high quality, anti-corrosion performance.

Ease of Application: Can be applied using conventional application equipment.

|

Product Properties |

|

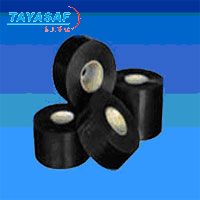

Backing

Polyethylene, stress-crack resistant with high temperature stabilizers. Color: Black. |

|

Adhesive

Engineered butyl alloy with synthetic resins and additives for curing when on primed pipe at elevated temperature. |

|

Physical Properties |

English |

Metric |

|

Total thickness

Backing thickness

Adhesive thickness

Tensile strength

Elongation

Adhesion to primed steel plate |

25 mil

13 mil

12 mil

40 lb/in

400%

250 oz/in |

0.64 mm

0.33 mm

0.31 mm

70 N / 10 mm

400%

20 N / 10 mm |

|

Electrical & Moisture |

English |

Metric |

|

Dielectric strength

Insulation resistance

Volume resistivity

Specific resistance

Water vapor transmission rate |

22 kV

> 1012 Ohm in

> 1015 Ohm in

7 x 1016 Ohm ft2

< 0.04 gm/100 in2/24 hr |

22 kV

> 1012 Ohm cm

> 1015 Ohm cm

6 x 1096 ohm m2

< 0.6 gm/m2/24 hr |

|

Note: Dielectric strength is not intended as a suggested holiday voltage. Refer to NACE Standard RP-02-74 for recommended holiday voltage. |

|

Temperature Range |

English |

Metric |

|

Normal application

Norma continuous service

Interim short interval operating temperature |

-30°F to 160°F

-30°F to 200°F

-30°F to 220°F |

-34°C to 71°C

-34°C to 93°C

-34°C to 104°C |

|

Test Methods |

|

1. ASTM D 100

2. ASTM D 149

3. ASTM D 257

4. ASTM F 1249 (100°F, 100% R.H.)

5. DIN 30672 |

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比