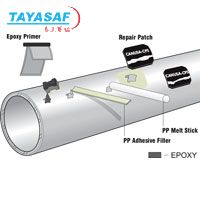

System Description

Polyken #934 is a cold applied tape coating system designed for the corrosion protection of field joints, fittings, and specialty piping. The highly conformable backing and thick, aggressive adhesive also make it the ideal repair system for all types of main line coatings. The Polyken #934 tape with very tacky adhesive has a release plastic liner to enable proper unwinding of the roll. Whether used as a double wrap system or as a single wrap with a mechanical layer, the Polyken #934 tape coating system is universally specified in the oil, gas and water industries.

Product Features & Benefits

Heavy duty adhesive.

Ensures a strong bond & impervious seal.

Conformable to irregular shapes.

Offers a solution for nearly every application.

Thick, aggressive adhesive.

Very useful as repair system for line coatings..

Worldwide reference lists.

Established in-ground history.

Complies with AWWA Standard C-209.

Reliable, high-performance corrosion protection.

Compatible with generic plant coating systems.

Versatile.

Product Selection Guide

|

|

934-35 & 934-50 |

|

Max operating temperature |

66°C (150°F) |

|

Recommended primer |

Polyken 1027 or 1033A |

|

Additional mechanical layer |

Polyken 955 or 954 |

|

Compatible line coatings |

PE, FBE, Tape & Coal Tar |

|

Recommended pipe preparation |

ST 2 1/2 - ST 3 |

|

Performance |

AWWA C-209 |

|

Performance |

AWWA C-209 |

Product Construction

|

|

934-35 |

934-50 |

|

Backing |

7 mils (0.178 mm) |

10 mils (0.254 mm) |

|

Adhesive |

28 mils (0.711 mm) |

40 mils (1.016 mm) |

|

Backing color

(other colors available on request) |

White |

White |

Product Properties

|

Product Properties |

Test method |

Typical Value

#934-35 |

Typical Value

#934-50 |

|

Tensile Strength |

ASTM D1000 |

15 lbs/in

(26 N/cm) |

25 lbs/in

(44 N/cm) |

|

Elongation |

ASTM D1000 |

150% |

|

Peel Adhesion to Primed

Steel |

ASTM D1000 |

225 oz/in

(25 N/cm) |

320 oz/in

(35 N/cm) |

|

Cathodic Disbondment |

ASTM G8 |

0.25 in radius

(6.4 mm) |

0.38 in radius

(9.7 mm) |

|

Water Vapor transmission |

ASTM E96B |

0.02 perm |

|

Water Vapor Transmission Rate |

ASTM F1249

(100°F, 100% RH) |

0.05 g / 100 in2 / 24hr

(0.8 g/m2 / 24 hr) |

|

Volume Resistivity |

ASTM E257 |

4 x 1014 ohm-cm |

|

Dielectric Breakdown |

ASTM D1000 |

650 volts/mil

(25.6 kV/mm) |

600 volts/mil

( 23.6 kV/mr |

|

Dielectric Strength |

ASTM D149 |

23 kV |

30 kV |

|

Insulation resistance |

ASTM D1000 |

1.4 x 107 MOhm |

2.0 x 107 MOhm |

泰亚赛福 —— 世界领先的检测仪器集成供应商

泰亚赛福 —— 世界领先的检测仪器集成供应商

您当前的位置:

您当前的位置:

加入对比

加入对比