DST1200尺寸稳定性测试仪

| 订货号: | MM-72932-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 1

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

FIBRO's DST 1200 is an automated testing instrument for optical evaluation of in-plane deformation across a test sample surface. Designed for measurements related to hygroexpansivity, tensile forces, curl and cockling, the DST 1200 records dimensional changes when a test specimen is exposed to varying moisture, temperature or tension.

As dimensional changes can cause production problems such as misregister in four color offset printing as well as runnability problems, knowledge of your material's behavior under different conditions enables you to adjust your process to compensate.

With the DST 1200, you can establish the dynamic quality limits necessary to meet your customers' needs. Testing capabilities include:

Dynamics of hygroexpansion

Creep deformation of corrugated boxes; moisture-induced creep

Tensile creep and stress relaxation

Fiber orientation

Mechanosorptive effects in wood

Strain analysis of wooden beams and metals

Features:

Optical non-contact evaluation of in-plane deformation caused by humidity, temperature and tension

Detects cockling as well as in-plane displacements down to 1 u across an area of 50 x 50 mm

Allows dynamic visual and statistical evaluation

Automatic cyclic testing of hygroexpansion with optional desktop climate chamber

Option: Climate Chamber for evaluation of hygroexpansion

Once the test is defined in the database, the climate chamber is operated automatically from the computer. Neat, clean and simple to use, the chamber runs time-consuming experiments by itself - freeing you to do other work.

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

SK-1260温度计订货号:TA-02329-00

SK-1260温度计订货号:TA-02329-00 uvex优唯斯口罩3310订货号:TA-01106-00

uvex优唯斯口罩3310订货号:TA-01106-00 日本北川一氧化碳106SA检测管订货号:TA-01308-00

日本北川一氧化碳106SA检测管订货号:TA-01308-00

红外分析仪配件--测量池订货号:TA-01403-00 Power250便携式多功能电源订货号:TA-01313-00

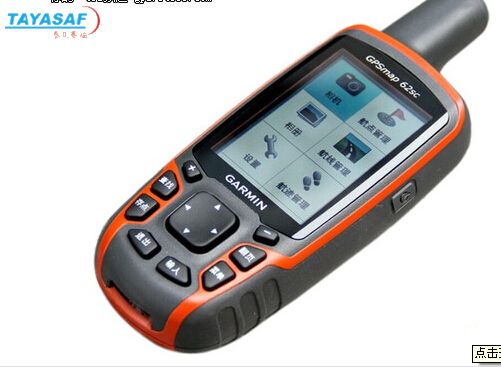

Power250便携式多功能电源订货号:TA-01313-00 佳明621SC定位仪订货号:TA-01311-00

佳明621SC定位仪订货号:TA-01311-00 奥地利E+E风速仪EE66-VCK200D02订货号:TA-01291-00

奥地利E+E风速仪EE66-VCK200D02订货号:TA-01291-00

固态气溶胶发生器SAG 410/H订货号:TA-02354-00 普通铂热电阻 WZP-231 Pt100 0~150℃ 250mm订货号:TA-02224-00

普通铂热电阻 WZP-231 Pt100 0~150℃ 250mm订货号:TA-02224-00

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-72932-00 | DST1200尺寸稳定性测试仪 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

品牌简介

美国Thwing-Albert服务于测试行业超过了一个世纪,所生产的测试仪器根据各种测试需求能提供最好的解决方案,美国Thwing-Albert完全承诺客户、值得信赖。产品包括粉碎机 、鼓…美国Thwing-Albert服务于测试行业超过了一个世纪,所生产的测试仪器根据各种测试需求能提供最好的解决方案,美国Thwing-Albert完全承诺客户、值得信赖。产品包括粉碎机 、鼓形干燥机、实验室搅拌器、扶轮鼓刀、样品裁刀、油墨测试仪、吸收性测试仪等等。

您最近浏览的商品

美国Thwing-Albert

美国Thwing-Albert