压差计

| 订货号: | MM-72529-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 1

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

MAGNEHELIC®, PHOTOHELIC®, MINIHELIC®, and DIGIHELIC®

Differential Pressure Gauges/Controller

Differential Pressure Gauges/Controller

Measure and control both positive and negative low air or gas pressures

Provide an ideal way of monitoring and controlling the positive pressure differential required for cleanrooms

Enable you to meet FED STD 209E regarding cleanroom pressure

Ideal for measuring differential pressure in gloveboxes and air flow in exhaust hoods

MAGNEHELIC® Principle ensures wear-free accuracy within 2% of full scale

Resists shock and vibration

Available in a number of pressure gauges to suit a wide range of applications, such as gauging air filters, monitoring air conditioning systems, and measuring static air pressure and air vehicles

If your facility incorporates a laminar flow cleanroom, these MAGNEHELIC® and PHOTOHELIC® differential pressure gauges can help you maintain the positive pressure necessary to block inrushing contaminants that can damage sensitive materials and operations. In doing so, they also help to meet the requirements and recommendations set forth in FED STD 209E which specifies that a minimum positive pressure of 0.05" of water differential be maintained between the cleanroom and adjacent areas.

Chatterless, Wear-Free Accuracy

These gauges incorporate an exclusive MAGNEHELIC® Principle that eliminates wear, backlash, and hysteresis. The result is a remarkably high standard of accurate, dependable gauge performance at a modest price.

These gauges incorporate an exclusive MAGNEHELIC® Principle that eliminates wear, backlash, and hysteresis. The result is a remarkably high standard of accurate, dependable gauge performance at a modest price.

This MAGNEHELIC® Principle is a method of transmitting the effects of changes in air pressure from a diaphragm to an indicating pointer—by means of magnetic linkage and without the use of gears or other direct mechanical linkages. This system avoids wear and physical contact, which might destroy the accuracy and sensitivity of the instrument. It delivers accuracy to within 2% of full scale.

MAGNEHELIC®, PHOTOHELIC®, MINIHELIC®, and DIGIHELIC®

Differential Pressure Gauges/Controller

Differential Pressure Gauges/Controller

Measure and control both positive and negative low air or gas pressures

Provide an ideal way of monitoring and controlling the positive pressure differential required for cleanrooms

Enable you to meet FED STD 209E regarding cleanroom pressure

Ideal for measuring differential pressure in gloveboxes and air flow in exhaust hoods

MAGNEHELIC® Principle ensures wear-free accuracy within 2% of full scale

Resists shock and vibration

Available in a number of pressure gauges to suit a wide range of applications, such as gauging air filters, monitoring air conditioning systems, and measuring static air pressure and air vehicles

If your facility incorporates a laminar flow cleanroom, these MAGNEHELIC® and PHOTOHELIC® differential pressure gauges can help you maintain the positive pressure necessary to block inrushing contaminants that can damage sensitive materials and operations. In doing so, they also help to meet the requirements and recommendations set forth in FED STD 209E which specifies that a minimum positive pressure of 0.05" of water differential be maintained between the cleanroom and adjacent areas.

Chatterless, Wear-Free Accuracy

These gauges incorporate an exclusive MAGNEHELIC® Principle that eliminates wear, backlash, and hysteresis. The result is a remarkably high standard of accurate, dependable gauge performance at a modest price.

These gauges incorporate an exclusive MAGNEHELIC® Principle that eliminates wear, backlash, and hysteresis. The result is a remarkably high standard of accurate, dependable gauge performance at a modest price.

This MAGNEHELIC® Principle is a method of transmitting the effects of changes in air pressure from a diaphragm to an indicating pointer—by means of magnetic linkage and without the use of gears or other direct mechanical linkages. This system avoids wear and physical contact, which might destroy the accuracy and sensitivity of the instrument. It delivers accuracy to within 2% of full scale.

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

SK-1260温度计订货号:TA-02329-00

SK-1260温度计订货号:TA-02329-00 uvex优唯斯口罩3310订货号:TA-01106-00

uvex优唯斯口罩3310订货号:TA-01106-00 日本北川一氧化碳106SA检测管订货号:TA-01308-00

日本北川一氧化碳106SA检测管订货号:TA-01308-00

红外分析仪配件--测量池订货号:TA-01403-00 Power250便携式多功能电源订货号:TA-01313-00

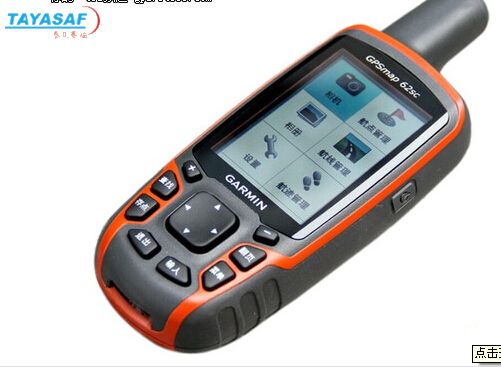

Power250便携式多功能电源订货号:TA-01313-00 佳明621SC定位仪订货号:TA-01311-00

佳明621SC定位仪订货号:TA-01311-00 奥地利E+E风速仪EE66-VCK200D02订货号:TA-01291-00

奥地利E+E风速仪EE66-VCK200D02订货号:TA-01291-00

固态气溶胶发生器SAG 410/H订货号:TA-02354-00 普通铂热电阻 WZP-231 Pt100 0~150℃ 250mm订货号:TA-02224-00

普通铂热电阻 WZP-231 Pt100 0~150℃ 250mm订货号:TA-02224-00

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-72529-00 | 压差计 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

品牌简介

美国terra universal公司是世界领先的设计者和制造者,其产品包括洁净室和实验室设备、干燥机、手套箱、干箱、手推车、专用柜等等。terra universa已成为此行业的制造专家,…美国terra universal公司是世界领先的设计者和制造者,其产品包括洁净室和实验室设备、干燥机、手套箱、干箱、手推车、专用柜等等。terra universa已成为此行业的制造专家,其产品被应用在关键环境当中,已有30多年的设计和制造经验。

您最近浏览的商品

美国terra universal

美国terra universal