防腐蚀钢管支架

| 订货号: | MM-26731-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

|

|

|

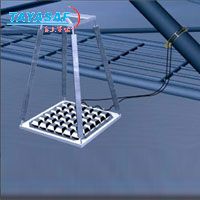

I-Clip shown in situ on a saddle clamp support. |

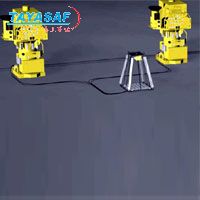

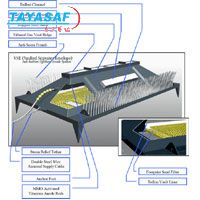

I-Clip retrofitted or pre-installed in Grinnell clamps. |

Description

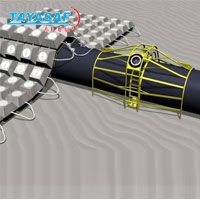

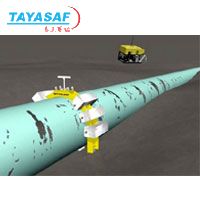

I-Clip by Deepwater is an individual pipe support clip installed on the inside diameter of a pipe saddle (≤10 foot diameter). The clips themselves are mechanically held in place, allowing them to be retrofitted easily along existing pipe runs. New Grinnell and cradle-style supports can also be easily fitted with I-Clip systems. I-Clips are made out of a variety of materials, suited for elevated temperatures and large weight loads.

I-Clips are available to fit all standard size Grinnell clamps and pipe Saddles. I-Clips can be installed in new or existing pipe support clamps.

Applications

Pipe cradle retrofits

Large diameter band clamps

Concrete or timber pier supports

High load riser clamps

Key design points

Half-round shape

The half-round shape minimizes contact between the pipe and the support, eliminating the crevice. Keeping water out keeps corrosion at bay.

The half-round shape minimizes contact between the pipe and the support, eliminating the crevice. Keeping water out keeps corrosion at bay.

Maintenance

I-Clips also provides an electrically isolated stand-off between the pipe and the supporting beam or saddle clamp. This allows for easy maintenance and inspection, while preventing galvanic corrosion between dissimilar metals (the pipe and support).

I-Clips also provides an electrically isolated stand-off between the pipe and the supporting beam or saddle clamp. This allows for easy maintenance and inspection, while preventing galvanic corrosion between dissimilar metals (the pipe and support).

Durability

The I-Clip also has excellent compressive strength, UV stability, and a very low friction coefficient, ensuring reliable service for as long as the pipe requires it.

The I-Clip also has excellent compressive strength, UV stability, and a very low friction coefficient, ensuring reliable service for as long as the pipe requires it.

Specifications Specifications Below are the basic specifications for I-Rod and T-Rod HT, the materials used to make the I-Clip. Deepwater has also begun to offer PEEK material for environments that prove too severe for either (though these instances are rather rare). For information on PEEK, or a specifications for any other aspect of Deepwater's pipe support systems, please contact Farwest Corrosion Control Company. |

|

I-Clip Dimensions for Grinnell Clamps

|

|

Pipe Diameter |

Clamp ID (A) |

Clamp Thickness (T) |

Clamp Width (W) |

Internal I-Clip Height |

No. Clips Required |

I-Clip Height |

I-Clip Length |

I-Rod Diameter |

Part No. |

|

3 |

4" |

0.250" |

1.00" |

0.25" |

4 |

0.688" |

1.50" |

1.5" |

IRD0190 |

|

4 |

5" |

0.250" |

1.25" |

0.25 |

4 |

0.688" |

1.75" |

1.5" |

IRD0191 |

|

6 |

7.125" |

0.375" |

1.50" |

0.25 |

6 |

0.688" |

2.00" |

1.5 |

IRD0192 |

|

8 |

9.125" |

0.375" |

1.50" |

0.25 |

8 |

0.688" |

2.00" |

1.5" |

IRD0193 |

|

10 |

11.25" |

0.500" |

2.00" |

0.25 |

8 |

0.688" |

2.50" |

1.5" |

IRD0194 |

|

12 |

12.75" |

0.500" |

2.00" |

0.25 |

8 |

0.688" |

2.50" |

1.5" |

IRD0195 |

|

14 |

14" |

0.500" |

2.50" |

0.25 |

8 |

0.688" |

3.00" |

1.5" |

IRD0196 |

|

16 |

16" |

0.500" |

2.50" |

0.25 |

10 |

0.688" |

3.00" |

1.5" |

IRD0197 |

|

18 |

18" |

0.625" |

2.50" |

0.25 |

10 |

0.688" |

3.00" |

1.5" |

IRD0198 |

|

20 |

20" |

0.625" |

2.50" |

0.25 |

10 |

0.688" |

3.00" |

1.5" |

IRD0199 |

|

24 |

24" |

0.625" |

3.00" |

0.25 |

12 |

0.688" |

3.50" |

1.5" |

IRD0200 |

|

28 |

28" |

0.625" |

3.00" |

0.25 |

14 |

0.688" |

3.50" |

1.5" |

IRD0201 |

|

30 |

30" |

0.750" |

4.00" |

0.25 |

16 |

0.688" |

4.50" |

1.5" |

IRD0202 |

|

32 |

32" |

0.750" |

4.00" |

0.25 |

16 |

0.688" |

4.50" |

1.5" |

IRD0203 |

|

I-Clip Dimensions for Pipe Saddles

|

|

Nominal Pipe Size |

Clamp Radius (R) |

Cradle Thickness (T) |

Cradle Width (W) |

Arc Length |

I-Clip Height |

Internal Height of I-Clip |

No. Clips Required |

I-Clip Length |

I-Rod Diameter |

Part No. |

|

3" |

2" |

0.250" |

4" |

4" |

0.688" |

0.25" |

2 |

4.5" |

1.5" |

IRD0204 |

|

4" |

2.5" |

0.375" |

4" |

5" |

0.688" |

0.25" |

2 |

4.5" |

1.5" |

IRD0205 |

|

6" |

3.5625" |

0.500" |

4" |

7" |

0.688" |

0.25" |

3 |

4.5" |

1.5" |

IRD0206 |

|

8" |

4.5625" |

0.500" |

4" |

9" |

0.688" |

0.25" |

4 |

4.5" |

1.5" |

IRD0207 |

|

10" |

5.625" |

0.500" |

4" |

11" |

0.688" |

0.25" |

4 |

4.5" |

1.5" |

IRD0208 |

|

12" |

N / A |

0.500" |

4" |

13" |

0.688" |

0.25" |

4 |

4.5" |

1.5" |

IRD0209 |

|

14" |

N / A |

0.500" |

4" |

15" |

0.688" |

0.25" |

5 |

4.5" |

1.5" |

IRD0210 |

|

16" |

N / A |

0.500" |

4" |

17" |

0.688" |

0.25" |

5 |

4.5" |

1.5" |

IRD0211 |

|

18" |

N / A |

0.500" |

4" |

19" |

0.688" |

0.25" |

6 |

4.5" |

1.5" |

IRD0212 |

|

20" |

N / A |

0.500" |

6" |

21" |

0.688" |

0.25" |

6 |

6.5" |

1.5" |

IRD0213 |

|

24" |

N / A |

0.500" |

6" |

25" |

0.688" |

0.25" |

6 |

6.5" |

1.5" |

IRD0214 |

|

28" |

N / A |

0.500" |

6" |

29" |

0.688" |

0.25" |

7 |

6.5" |

1.5" |

IRD0215 |

|

30" |

N / A |

0.500" |

6" |

31" |

0.688" |

0.25" |

7 |

6.5" |

1.5" |

IRD0216 |

|

32" |

N / A |

0.500 |

6" |

34" |

0.688" |

0.25" |

8 |

6.5" |

1.5" |

IRD0217 |

I-Clip Material Overview

|

Material |

Max Operating Temp |

Melting Point |

Compr. Strength |

Maximum Load | ||

|

ºF |

ºC |

ºF |

ºC |

PSI |

Kg | |

|

I-Rod |

194 |

90 |

329 |

165 |

16000 |

3630 |

|

I-Rod HT |

340 |

171 |

N/A |

N/A |

22000 |

5000 |

|

PEEK |

480 |

249 |

644 |

340 |

20000 |

4550 |

|

PEEK HT |

600 |

315 |

705 |

374 |

20000 |

4550 |

|

PEEK BG |

480 |

249 |

N/A |

N/A |

29000 |

6600 |

I-Rod (Standard) Full Specifications

|

Property Value |

Units |

ASTM Test |

Value |

|

Density, 73º F |

- |

D792 |

1.41 |

|

Tensile Strength, 73º F |

psi |

D638 |

9,800 |

|

Tensile Modulus of Elasticity, 73º F |

psi |

D638 |

440,000 |

|

Elongation (at break), 73º F |

% |

D638 |

30-60 |

|

Flexural Modulus of Elasticity, 73º F |

psi |

D790 |

455,000 |

|

Flexural Strength, 73º F |

psi |

D790 |

13,800 |

|

Compressive Strength, 10% def, 73º F |

psi |

D695 |

16,000 |

|

Coefficient of Friction (dry vs steel) Dynamic |

- |

PTM 55007 |

0.25 |

|

IZOD Impact (notched), 73º F |

ft-lbs/in of notch |

D256 |

1.5 |

|

Hardness, Rockwell, 73º F |

- |

D785 |

119-122 |

|

Deformation Under Load |

% |

D621 |

1.0 |

|

Melting Point |

ºF |

D3418 |

329 |

|

Coefficient of Linear Expansion |

in/in/ºF |

E831 |

5.8 x 10-5 |

|

Continuous Service Temperature |

ºF |

- |

194 |

|

Heat Deflection Temperature, 264 psi |

ºF |

D648 |

220 |

|

Flammability Rating |

- |

VL94 |

HB |

|

Volume Resistivity |

Ohm-cm |

D257 |

1.0 x 1015 |

|

Dielectric Strength, Short Term |

V/mm |

D149 |

420 |

I-Rod (High-Temperature) Full Specifications

|

Property Value |

Units |

ASTM Test |

Value |

|

Density, 73º F |

- |

D792 |

1.28 |

|

Tensile Strength, 73º F |

psi |

D638 |

16,500 |

|

Tensile Modulus of Elasticity, 73º F |

psi |

D638 |

475,000 |

|

Elongation (at break), 73º F |

% |

D638 |

80 |

|

Flexural Modulus of Elasticity, 73º F |

psi |

D790 |

500,000 |

|

Flexural Strength, 73º F |

psi |

D790 |

20,000 |

|

Compressive Strength, 10% def, 73º F |

psi |

D695 |

22,000 |

|

Coefficient of Friction (dry vs steel) Dynamic |

- |

PTM 55007 |

0.42 |

|

IZOD Impact (notched), 73º F |

ft-lbs/in of notch |

D256 |

0.5 |

|

Hardness, 73º F |

- |

D785 |

R125 / M112 |

|

Melting Point |

ºF |

D3418 |

N/A |

|

Coefficient of Linear Expansion |

in/in/ºF |

E831 |

3.1 x 10-5 |

|

Continuous Service Temperature |

ºF |

- |

340 |

|

Heat Deflection Temperature, 264 psi |

ºF |

D648 |

392 |

|

Flammability Rating |

- |

UL94 |

V-O |

|

Volume Resistivity |

Ohm-cm |

D257 |

6.7 x 1017 |

|

Dielectric Strength, Short Term |

V/mm |

D149 |

830 |

|

Thermal Conductivity |

BTU-in/ ft2 hr ºF |

C177 |

0.90 |

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

延长平台寿命的阴极保护订货号:MM-26720-00

延长平台寿命的阴极保护订货号:MM-26720-00 深水资源CP系统订货号:MM-26721-00

深水资源CP系统订货号:MM-26721-00 延长管道寿命的阴极保护订货号:MM-26722-00

延长管道寿命的阴极保护订货号:MM-26722-00 低成本阴极保护系统订货号:MM-26723-00

低成本阴极保护系统订货号:MM-26723-00 CP-Mat管道的阴极防护垫订货号:MM-26724-00

CP-Mat管道的阴极防护垫订货号:MM-26724-00 大型结构生命扩展的阴极保护订货号:MM-26725-00

大型结构生命扩展的阴极保护订货号:MM-26725-00 延长小型结构寿命的阴极保护订货号:MM-26726-00

延长小型结构寿命的阴极保护订货号:MM-26726-00 恶劣条件下码头的阴极保护订货号:MM-26727-00

恶劣条件下码头的阴极保护订货号:MM-26727-00 自埋CP阳极订货号:MM-26728-00

自埋CP阳极订货号:MM-26728-00 海底固定装置订货号:MM-26729-00

海底固定装置订货号:MM-26729-00 阴极保护夹具订货号:MM-26730-00

阴极保护夹具订货号:MM-26730-00 燃气电子601型绝缘子检测仪订货号:MM-26732-00

燃气电子601型绝缘子检测仪订货号:MM-26732-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-26731-00 | 防腐蚀钢管支架 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

您最近浏览的商品

美国MI

美国MI