Model Oxys Atex氧气分析仪

| 订货号: | MM-40582-00 |

| 产地: | 意大利 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 1

- 2

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

In situ mounting

Excellent stability.

Very fast response time.

Unaffected by high Sulphur and HCl.

No calibration required.

Absolutely safe.

Approved for zone 1

Inexpensive

This analyzer is an excellent solution for oxygen measuring in flue gas in the radiant section at high temperature. It guarantee a very fast response time and an accurate measure which is not affected by the outside air, which normally penetrates between the combustion chamber and the stack. The accurate compensation of the output of the zirconia cell to the temperature of the process eliminate any Zero and Span drift. Specific test carried out on purpose have demonstrated a stability within 0,1% O2 during twelve months.

The probe, totally ceramic, is unaffected by the most aggressive atmosphere and with high particulate content, like the combustion chamber of incinerators of contaminated liquids and gases.

The very competitive price is compatible with the high performance due to the simple construction of the analyzer.

The equipment is composed by the probe (produced in three different lengths), the field transmitter with active barriers in Ex housing and the Flowmeter box. The protection is: EEx d IIC 2G c T4 fully ATEX approved – IP 65. The probe, that has no electric power supply, is an intrinsically safe device. It generates signals lower than the dangerous limits according the safety norms.

The probe mod. 4153 ia is based on a stabilized zirconium oxide cell which is warmed by the temperature of the process. Inside the probe is fitted a B type thermocouple (that does not need compensated cable). The signals of the thermocouple is used by the electronic unit to continuously compensate the output of the zirconia cell to the real temperature of the probe. The flue gas does not circulate inside the probe; it get in contact with the measuring cell on the tip of the probe by diffusion The probe is connected to the process normally by a 4” 150 RF ANSI flange or similar. The probe can be optionally equipped with a housing which contain the flame arresters, which completely divides the atmosphere inside and outside the furnace.

The microprocessor based field transmitter mod. 8045 is housed in an Ex enclosure with glass window for display reading. Inside the enclosure a double channel barrier is housed. Magnetic switches that can be operated without opening the housing by using a magnet through the glass window. They enable to manage all functions of the electronic unit.

The flow-meters box mod. 60 receives instrumentation air and gas from gas cylinder and drives reference air and test air and gas to the probe.

TECHNICAL SPECIFICATIONS

Measuring field: 0,0001-25% O2 by volume.

Precision:±0,5% of the theoretical value or 0,1% O2 (which ever is the greater)

Stability: within 1%.

Response time (T90): zirconia cell < 1", the hole system < 15"

Storage temperature: probe -40 °C/+80°C.

Working temperature: probe 500 ÷ 1600°C for the temperature of the process. Room temp.< 150 °C for the head of the probe; converter and barrier: -20 °C/ +50 °C.

Outputs: analog 4÷20 mA 500 ohm or 0 – 10 V 10 mA linear on one of the following fields: 0÷1999 ppm; 0÷5%; 0÷10%; 0÷25% O2. If the fault alarm is activated the analog output is forced to 2 mA or 0 V.

Alarms Potential free (SPST) contacts, O2 high and low, fault (fail safe) service and calibration in progress. For all contacts 250 V, 1 A max.

Dumper: time constant adjustable between 0 and 900 sec.

Power supply: 115V and 230 V ±10%, 50÷60 Hz, 50 V.A max. Safety according EN 61010

Protection: “c” IIC T4 – IP 65.

EMC According E 50081 and EN 50082

Connecting cable: 4x1.5 shielded. Max length 100 mt.

Probe dimensions: Immersion lengths = 650, 500, 310 mm; Diameter = 27 mm; With suitable extension tubes 1500 mm maximum immersion length can be reached.

Pneumatic connections Inox compression fittings for 6x4 tubing or ¼” NPT-F

Options: Hart & Mod-bus protocols

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

OX-415便携式红外线氧气检测仪订货号:MM-00248-00

OX-415便携式红外线氧气检测仪订货号:MM-00248-00 GasbadgePlus氧气检测仪订货号:MM-00459-00

GasbadgePlus氧气检测仪订货号:MM-00459-00 C16手持式氧气(O2、0-5/25%)检测仪订货号:MM-00561-00

C16手持式氧气(O2、0-5/25%)检测仪订货号:MM-00561-00 PGM-1100氧气报警仪订货号:MM-00884-00

PGM-1100氧气报警仪订货号:MM-00884-00 GAXT单一防水型单一氧气检测仪订货号:MM-00968-00

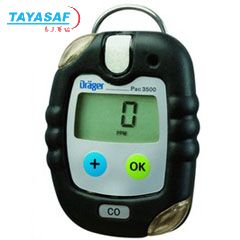

GAXT单一防水型单一氧气检测仪订货号:MM-00968-00 Pac3500氧气检测仪订货号:MM-00994-00

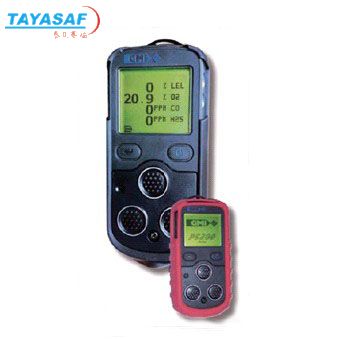

Pac3500氧气检测仪订货号:MM-00994-00 ps200氧气检测仪(带泵)订货号:MM-84973-00

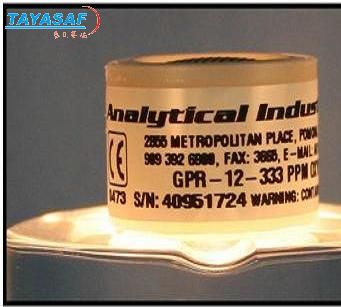

ps200氧气检测仪(带泵)订货号:MM-84973-00 GPR-11-32-4百分比氧传感器订货号:TA-00212-00

GPR-11-32-4百分比氧传感器订货号:TA-00212-00

XO-326IISA氧气浓度检测仪订货号:TA-02282-00

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-40582-00 | Model Oxys Atex氧气分析仪 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机840 / 211 或拨0转总机

上海:021-54248686 分机840 / 211 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,以最优的价格+完善的售后服务体系向您提供产品。“服务第一、质量第一、价格最低”!

品牌简介

您最近浏览的商品

意大利FER

意大利FER