Series 3000氧气分析仪

| 订货号: | MM-40385-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

The Series 3000 Trace Oxygen Analyzers are rugged, microprocessor-controlled instruments designed for continuous or intermittent measurement of trace concentrations of oxygen. The Series 3000 Trace Oxygen Analyzers are available in single or three ranges, from 0-1 to 0-10,000 parts per million (ppm).

|

Features |

Benefits |

|

Safe to use |

Some oxygen sensors must be initially filled with potassium hydroxide (caustic), a hazardous material. The Series 3000 Trace Oxygen Sensor is sealed; there is no such safety hazard. |

|

Economically priced |

Affords savings up to 50% and more over other electro- chemical oxygen analyzers. |

|

Minimum maintenance |

The Series 3000 Sensor never requires routine addition of water or potassium hydroxide. Operating costs are reduced. |

|

Full sensor warranty |

Ensures cost-effective operation. Beware of "limited" or "pro-rated" sensor warranties. Warranty replacement of one of our competitor's sensor can exceed $3,000. |

|

Visual and audible alarms |

Ensures the highest level of protection. |

|

Optional RS-232C or RS-485 communications |

Control several monitors on one communications channel along with security code protection. |

System Description

Featured with the instrument is an advanced electrochemical oxygen sensor that provides exceptional performance, accuracy, and stability. Its enhanced mechanical design ensures longer sensor life, and virtually eliminates leakage of electrolyte, a nagging problem with wet cells.

Featured with the instrument is an advanced electrochemical oxygen sensor that provides exceptional performance, accuracy, and stability. Its enhanced mechanical design ensures longer sensor life, and virtually eliminates leakage of electrolyte, a nagging problem with wet cells.

The eloquence of the Series 3000 Trace Oxygen Analyzers are their ease of use. The Series 3000 Trace Oxygen Analyzers are equipped with three oxygen alarms and one status alarm relay, all of which can be configured for fail-safe operation. In addition to the alarm relays, each instrument is equipped with audible and visual alarm indicators. Available in a wide number of mechanical configurations from explosion proof (NEMA 7) to watertight (NEMA 4), the Series 3000 Trace Oxygen Analyzer affords maximum flexibility to meet the demands of the process control market. The Series 3000 Trace Oxygen Analyzer is priced thousands of dollars less than some other manufacturers. So before making that purchase decision, we would be delighted to submit a quotation for your consideration.

Accuracy¹: ±1% of full scale (±5% fs 0-1ppm range)

Linearity: ±1%

Response Time: 90% of full scale response in less than 10 seconds (typical). Recovery time for ranges <10 ppm will depend on the prevailing conditions.

Sensor Type: Patented Ambient Temperature Electrochemical Sensor

Temperature Compensation: Standard

Operating Temperature:

Linearity: ±1%

Response Time: 90% of full scale response in less than 10 seconds (typical). Recovery time for ranges <10 ppm will depend on the prevailing conditions.

Sensor Type: Patented Ambient Temperature Electrochemical Sensor

Temperature Compensation: Standard

Operating Temperature:

40° to 100° F (5° to 38° C)

<40° F use heated sensor enclosure

>100° F cooling of sensor required

Warranty: 3 years electronics,1 year sensor

ELECTRICAL

Display: 0.4" (10.2 mm) high, 4-1/2 digit LCD

Resolution:

Display: 0.4" (10.2 mm) high, 4-1/2 digit LCD

Resolution:

0.1 ppm for ranges <100 ppm

1.0 ppm for ranges >100 ppm

Input Power: 115/230 VAC, 50-60Hz or 18-32 VDC. NICAD battery backup available as an option for some models.

Outputs: 4-20 mADC and 0-2 VDC standard. RS-232C or RS-485 optional. TTL output with 3 range instruments.

Oxygen Alarm Relays: Three (3) SPDT Form C contacts rated 10 A @ 30 VDC/115/230 VAC. User selectable for fail-safe or non fail-safe.

Instrument Status Alarm: Rated identically to the O2 relays

Audible Alarm: Internal buzzer with audible cancel

Outputs: 4-20 mADC and 0-2 VDC standard. RS-232C or RS-485 optional. TTL output with 3 range instruments.

Oxygen Alarm Relays: Three (3) SPDT Form C contacts rated 10 A @ 30 VDC/115/230 VAC. User selectable for fail-safe or non fail-safe.

Instrument Status Alarm: Rated identically to the O2 relays

Audible Alarm: Internal buzzer with audible cancel

SAMPLE GAS CHARACTERISTICS

Flow Rate: 1.0 to 2.0 SCFH (0.5 to 1.0 liter/min)

Sample Gas Temperature: 32° to 122° F (0° to 50° C)

Sample Gas Pressure: 0.1 to 1.0 psig (1.04 kg/cm² to 1.10 kg/cm²)

Entrained Solids:

Flow Rate: 1.0 to 2.0 SCFH (0.5 to 1.0 liter/min)

Sample Gas Temperature: 32° to 122° F (0° to 50° C)

Sample Gas Pressure: 0.1 to 1.0 psig (1.04 kg/cm² to 1.10 kg/cm²)

Entrained Solids:

<3 mg/ft³: no in-line filter required

>3 mg/ft³: in-line filter is required

Hydrocarbon Mist:

<0.7 mg/ft³: no in-line filter required

>0.7 mg/ft³: in-line filter is required

CONSTRUCTION²

Electronics Control Unit (Benchtop): Polycarbonate with a hinged clear front cover, rated NEMA 4X (IP 66)

Control Unit Dimensions:

Electronics Control Unit (Benchtop): Polycarbonate with a hinged clear front cover, rated NEMA 4X (IP 66)

Control Unit Dimensions:

9.45 in. (240.5 mm) length

6.50 in. (165.1 mm) width

6.20 in. (157.5 mm) depth

Gas Connections: 1/4" compression fittings

Sensor Mounting: Local or optional remote mounting

Sensor Mounting: Local or optional remote mounting

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

OX-415便携式红外线氧气检测仪订货号:MM-00248-00

OX-415便携式红外线氧气检测仪订货号:MM-00248-00 GasbadgePlus氧气检测仪订货号:MM-00459-00

GasbadgePlus氧气检测仪订货号:MM-00459-00 C16手持式氧气(O2、0-5/25%)检测仪订货号:MM-00561-00

C16手持式氧气(O2、0-5/25%)检测仪订货号:MM-00561-00 PGM-1100氧气报警仪订货号:MM-00884-00

PGM-1100氧气报警仪订货号:MM-00884-00 GAXT单一防水型单一氧气检测仪订货号:MM-00968-00

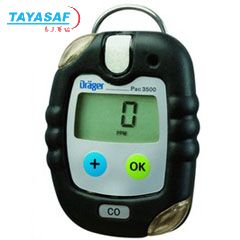

GAXT单一防水型单一氧气检测仪订货号:MM-00968-00 Pac3500氧气检测仪订货号:MM-00994-00

Pac3500氧气检测仪订货号:MM-00994-00 日本新宇宙XO-2200氧气检测仪,新宇宙氧气检测仪,便携式氧气检测仪订货号:MM-09314-00

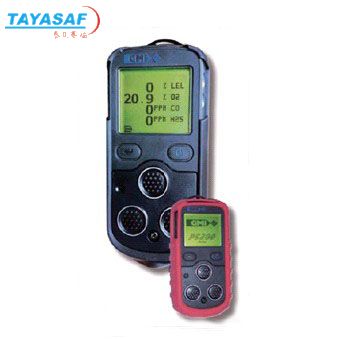

日本新宇宙XO-2200氧气检测仪,新宇宙氧气检测仪,便携式氧气检测仪订货号:MM-09314-00 ps200氧气检测仪(带泵)订货号:MM-84973-00

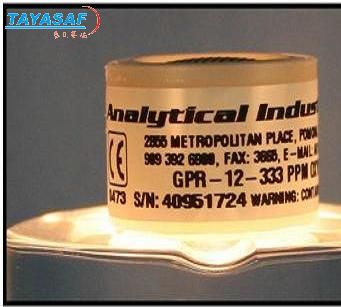

ps200氧气检测仪(带泵)订货号:MM-84973-00 GPR-11-32-4百分比氧传感器订货号:TA-00212-00

GPR-11-32-4百分比氧传感器订货号:TA-00212-00

XO-326IISA氧气浓度检测仪订货号:TA-02282-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-40385-00 | Series 3000氧气分析仪 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机840 / 211 或拨0转总机

上海:021-54248686 分机840 / 211 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

品牌简介

Alpha Omega Instruments仪器公司致力于用更好的产品满足于客户。随着当今世界经济的发展,为在全球基础上开展业务提供了很多机会和挑战。Alpha Omega Instruments仪器公司对…Alpha Omega Instruments仪器公司致力于用更好的产品满足于客户。随着当今世界经济的发展,为在全球基础上开展业务提供了很多机会和挑战。Alpha Omega Instruments仪器公司对产品的广度,以及应用经验的深度,做出了正确的建议,第一时间得到解决。Alpha Omega Instruments仪器公司有两个主要的企业集团。其光电集团制造的热电冷却器控制器与全球定位卫星,高分辨率光谱仪,激光表征设备,惯性制导系统,医疗诊断设备等被广泛应用。另一个为流程分析器集团,生产冷镜露点湿度计,跟踪仪,氧气分析仪,变送器,环境空气中的氧监视器,二氧化碳分析仪等。

您最近浏览的商品

美国Alpha Omega Instruments

美国Alpha Omega Instruments