Ultra 1000有毒气体/氧气传感器

| 订货号: | MM-40345-00 |

| 产地: | 美国 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

Features

RS-485 MODBUS Serial Output

4-20mA Analog Output

12-28 VDC Operation

Automated Non-Intrusive Calibration

Fully Adjustable Alarm Relay

Lower wiring costs

Description

Ultra 1000 series is a microprocessor based addressable sensor for toxic gas detection. The self- contained sensor features user friendly interface and menu driven calibration procedure and configuration.

The complete sensor consists of a stainless steel sensor head assembly, a user connection board and a transmitter board assembly. All of the sensor electronics are enclosed in an explosion proof instrument box. The unit’s modular design allows easy maintenance, troubleshooting and high reliability.

The unit provides a 4-20mA signal proportional to 0 to 100% of the detection range. In addition the sensor may be addressed via MODBUS RTU interface. The MODBUS output provides sensor status, alarm & fault conditions. Alarm levels can be programmed via MODBUS RTU or via magnetic switch on the face of the transmitter board assembly.

Ultra 1000 can be calibrated in less than 2 ½ minutes. The calibration and the set-up parameters are retained in a non-volatile memory.

Specifications

Sensor Type

Electrochemical

Measuring Range

|

Ammonia (NH3) |

50 ppm |

|

Carbon Monoxide (CO) |

100 & 1000 ppm |

|

Chlorine (CL2) |

10 ppm |

|

Chlorine Dioxide (CLO2) |

50 ppm |

|

Ethylene (C2H4) |

100 pm |

|

Ethylene Oxide (C2H4O) |

50 ppm |

|

Hydrogen Chloride (HCL) |

20 ppm |

|

Hydrogen Sulfide (H2S) |

100 ppm |

|

Hydrogen (H2) |

100 & 1000 ppm |

|

Hydrogen Cyanide (HCN) |

30 ppm |

|

Methyl Mercaptan (CH3SH) |

100 ppm |

|

Nitrogen Dioxide (NO2) |

20 ppm |

|

Nitric Oxide (NO) |

100 ppm |

|

Oxygen Deficiency (O2) |

25% |

|

Sulfur Dioxide (SO2) |

50 ppm |

Repeatability

± 2 % Full scale

Zero Drift

< 5% per year

Response Time

T90 < 30 seconds

Classification

Class I, division 1, Groups B,C & D

Operating Temperature

-4°F to +122°F (-20°C to +50°C)

Operating Humidity

15% to 90% RH, non-condensing

Display

2 lines by 8 Character LC Display with back light

Mechanical Specifications

Length: 7 inches (178 mm)

Width: 5 inches (127 mm)

Height: 4.5 inches (114 mm)

Status Indicators

Three-digit display for gas concentration, Alarm relay status, calibration mode and sensor fault status.

Input Power

14-28 VDC. 24 VDC nominal

Power Consumption

90mA @ 24 VDC Typical

Alarm Relays

Fully programmable.

0 to Full scale range of the sensor.

Latching or Non-Latching.

Relay Ratings

SPDT Form “C” type Relay contacts

5 Amps @ 250 VAC or 30 VDC

Analog Output

Linear 4-20mA (300 Ohms max. load)

2.0 mA - Calibration mode

< 1.0 mA - Sensor malfunction

Calibration

Non-Intrusive activated by internal magnetic switch

Cable Requirement

3 wire shielded cable. Max loop resistance 20 Ohms

Cable Entry Hub

Features

RS-485 MODBUS Serial Output

4-20mA Analog Output

12-28 VDC Operation

Automated Non-Intrusive Calibration

Fully Adjustable Alarm Relay

Lower wiring costs

Description

Ultra 1000 series is a microprocessor based addressable sensor for toxic gas detection. The self- contained sensor features user friendly interface and menu driven calibration procedure and configuration.

The complete sensor consists of a stainless steel sensor head assembly, a user connection board and a transmitter board assembly. All of the sensor electronics are enclosed in an explosion proof instrument box. The unit’s modular design allows easy maintenance, troubleshooting and high reliability.

The unit provides a 4-20mA signal proportional to 0 to 100% of the detection range. In addition the sensor may be addressed via MODBUS RTU interface. The MODBUS output provides sensor status, alarm & fault conditions. Alarm levels can be programmed via MODBUS RTU or via magnetic switch on the face of the transmitter board assembly.

Ultra 1000 can be calibrated in less than 2 ½ minutes. The calibration and the set-up parameters are retained in a non-volatile memory.

Specifications

Sensor Type

Electrochemical

Measuring Range

|

Ammonia (NH3) |

50 ppm |

|

Carbon Monoxide (CO) |

100 & 1000 ppm |

|

Chlorine (CL2) |

10 ppm |

|

Chlorine Dioxide (CLO2) |

50 ppm |

|

Ethylene (C2H4) |

100 pm |

|

Ethylene Oxide (C2H4O) |

50 ppm |

|

Hydrogen Chloride (HCL) |

20 ppm |

|

Hydrogen Sulfide (H2S) |

100 ppm |

|

Hydrogen (H2) |

100 & 1000 ppm |

|

Hydrogen Cyanide (HCN) |

30 ppm |

|

Methyl Mercaptan (CH3SH) |

100 ppm |

|

Nitrogen Dioxide (NO2) |

20 ppm |

|

Nitric Oxide (NO) |

100 ppm |

|

Oxygen Deficiency (O2) |

25% |

|

Sulfur Dioxide (SO2) |

50 ppm |

Repeatability

± 2 % Full scale

Zero Drift

< 5% per year

Response Time

T90 < 30 seconds

Classification

Class I, division 1, Groups B,C & D

Operating Temperature

-4°F to +122°F (-20°C to +50°C)

Operating Humidity

15% to 90% RH, non-condensing

Display

2 lines by 8 Character LC Display with back light

Mechanical Specifications

Length: 7 inches (178 mm)

Width: 5 inches (127 mm)

Height: 4.5 inches (114 mm)

Status Indicators

Three-digit display for gas concentration, Alarm relay status, calibration mode and sensor fault status.

Input Power

14-28 VDC. 24 VDC nominal

Power Consumption

90mA @ 24 VDC Typical

Alarm Relays

Fully programmable.

0 to Full scale range of the sensor.

Latching or Non-Latching.

Relay Ratings

SPDT Form “C” type Relay contacts

5 Amps @ 250 VAC or 30 VDC

Analog Output

Linear 4-20mA (300 Ohms max. load)

2.0 mA - Calibration mode

< 1.0 mA - Sensor malfunction

Calibration

Non-Intrusive activated by internal magnetic switch

Cable Requirement

3 wire shielded cable. Max loop resistance 20 Ohms

Cable Entry Hub

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

OX-415便携式红外线氧气检测仪订货号:MM-00248-00

OX-415便携式红外线氧气检测仪订货号:MM-00248-00 GasbadgePlus氧气检测仪订货号:MM-00459-00

GasbadgePlus氧气检测仪订货号:MM-00459-00 C16手持式氧气(O2、0-5/25%)检测仪订货号:MM-00561-00

C16手持式氧气(O2、0-5/25%)检测仪订货号:MM-00561-00 PGM-1100氧气报警仪订货号:MM-00884-00

PGM-1100氧气报警仪订货号:MM-00884-00 GAXT单一防水型单一氧气检测仪订货号:MM-00968-00

GAXT单一防水型单一氧气检测仪订货号:MM-00968-00 Pac3500氧气检测仪订货号:MM-00994-00

Pac3500氧气检测仪订货号:MM-00994-00 日本新宇宙XO-2200氧气检测仪,新宇宙氧气检测仪,便携式氧气检测仪订货号:MM-09314-00

日本新宇宙XO-2200氧气检测仪,新宇宙氧气检测仪,便携式氧气检测仪订货号:MM-09314-00 ps200氧气检测仪(带泵)订货号:MM-84973-00

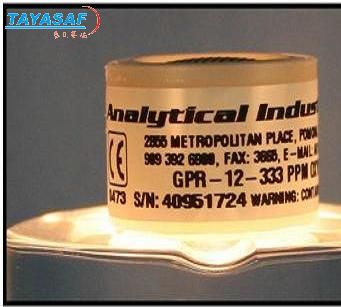

ps200氧气检测仪(带泵)订货号:MM-84973-00 GPR-11-32-4百分比氧传感器订货号:TA-00212-00

GPR-11-32-4百分比氧传感器订货号:TA-00212-00

XO-326IISA氧气浓度检测仪订货号:TA-02282-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-40345-00 | Ultra 1000有毒气体/氧气传感器 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机 或拨0转总机

上海:021-54248686 分机840 / 211 或拨0转总机

上海:021-54248686 分机840 / 211 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

品牌简介

您最近浏览的商品

美国pemtech

美国pemtech