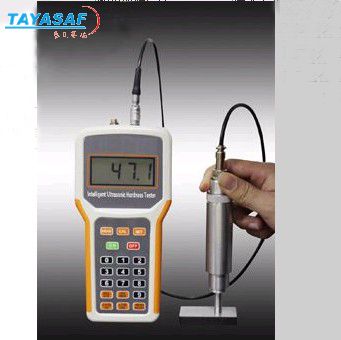

INATEST便携式超声波硬度计

| 订货号: | MM-62994-00 |

| 产地: | 俄罗斯 |

| 品牌: | |

| 开发编号: | N |

| 市场价: | ¥ |

| *此产品根据配置不同价格不同 |

| *此价格为参考价格,具体价格以订单合同为准 |

- 我在现场:

- 产品视频:

- 产品描述

- 技术参数

- 技术文档

- 相关产品

- 明细价格

- 购买流程

产品描述:

New hardness tester, based on UCI method and intended for express hardness measurements in laboratory, workshop and etc.

The distinctive instrument feature is absence of hard requirements to the cleanness and form of surface and positioning of sensor. Construction of indenter, allows to produce the stable measurings without depending on effort and time of pinning of sensor to the surface, providing exact measurings without application of stand.

Instrument allows to measure hardness of metals (steel, cast-iron, coloured metals and other), superficially consolidated layer (cementation, nitriding, etc.), and also galvanic coverages (chrome). Easy, in one button pressing, changing of scale provides rapid measuring on all basic scales: Brinell (HB), Rockwell (HRC, HRA, HRB), Vickers (HV), Shor(HSD).

The distinctive instrument feature is absence of hard requirements to the cleanness and form of surface and positioning of sensor. Construction of indenter, allows to produce the stable measurings without depending on effort and time of pinning of sensor to the surface, providing exact measurings without application of stand.

Instrument allows to measure hardness of metals (steel, cast-iron, coloured metals and other), superficially consolidated layer (cementation, nitriding, etc.), and also galvanic coverages (chrome). Easy, in one button pressing, changing of scale provides rapid measuring on all basic scales: Brinell (HB), Rockwell (HRC, HRA, HRB), Vickers (HV), Shor(HSD).

|

Memory: up to 6 000 results of measurements

with possibility of their transfer to PC 3 additional scales of hardness

Averaging of results of measurement |

Automatic switching-off

Graphic LCD with bightness correction

Mains power: build-in rechargeable battery

3 year warranty |

Basic Delivery Set

Inatest base unit

B-type probe (50N)

Power unit/ charger

PC cable

Software

Protective cover

Transport bag

Additional accessories

N-type probe with the diminished loading (only 10N) - for control of wares with enhanceable requirements to the size of imprint, galvanic coverages

S-type probe with the megascopic loading (100N), for control of wares with a badly geared-up surface

Shortened K-type probe with the diminished sizes (height - 70mm), for control into pipes, difficult of access places.

Hardness calibration blocks

Stand for a probe

Technical Characteristics

Measurement range (Rockwell scale)

20-70 HRC

Measurement range (Brinell scale)

90-460 HB

Measurement range (Vickers scale)

230-940 HV

Measurement range (Shore scale)

35-155 HSD

Measurement time

2 s

Radius of curvature of a surface

not less than 5 mm

Roughness of a testinglable surface no more

Ra 2,5

Thickness of a wall of a supervised vessel of pressure or the pipeline

not less than 1 mm

Scales

HRC, HB, HV, HSD, Rm + 3 additional

Number of measurements for definition of average value of hardness

up to 9

Quantity of remembered results of measurements in non-volatile memory

up to 6 000

Communication with PC

RS232

Mains power

build-in batterie 8,4V or via external plug-in power unit

Operating voltage

8,4 V

Operating temperature

up to -10 C to +45 C

Base Unit Dimensions (H x W x D)

150 mm x 80 mm x 40 mm

Weight with batteries

300 g

技术参数:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

技术文档:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

- 在线浏览:

- 文档下载:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

相关产品:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

MIC10超声波硬度计订货号:MM-00395-00

MIC10超声波硬度计订货号:MM-00395-00 DYNATEST SC硬度计订货号:MM-05748-00

DYNATEST SC硬度计订货号:MM-05748-00 MET-U1A超声波硬度计订货号:MM-00398-00

MET-U1A超声波硬度计订货号:MM-00398-00 MIC-20组合式超声硬度计订货号:MM-62991-00

MIC-20组合式超声硬度计订货号:MM-62991-00 SU-300超声波硬度计订货号:TA-00245-00

SU-300超声波硬度计订货号:TA-00245-00 SH-21超声波硬度计订货号:MM-00185-00

SH-21超声波硬度计订货号:MM-00185-00 AT200硬度计订货号:MM-05745-00

AT200硬度计订货号:MM-05745-00 MC-0449便携式超声硬度计订货号:MM-62992-00

MC-0449便携式超声硬度计订货号:MM-62992-00 EH-10超声波硬度计订货号:TA-00023-00

EH-10超声波硬度计订货号:TA-00023-00 HY-31超声波硬度计订货号:MM-00201-00

HY-31超声波硬度计订货号:MM-00201-00 MIC20超声波硬度计订货号:MM-01967-00

MIC20超声波硬度计订货号:MM-01967-00 德国KK MIC10DL超声波硬度计订货号:MM-62990-00

德国KK MIC10DL超声波硬度计订货号:MM-62990-00

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

明细价格:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

| 定货号 | 产品名称 | 规格配置 / 简介 | 市场价/(会员价) |

|---|---|---|---|

| MM-62994-00 | INATEST便携式超声波硬度计 | /() |

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

购买流程:

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

①购买产品:点击“生成订单”→填写产品数量、联系方式并提交→会员顾问订单处理→合同签订。

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

②咨询产品:请联系会员顾问或致电会员客服电话。

③如果您还不是我们的会员,请先注册。

④最小起订数量:1

注意:本产品唯一个人现金委托收款人,如汇入其它个人账户本公司不承担任何责任

维护担当:

上线时间:

投诉电话:13801126385 13911302309

联系方式

电话北京:400-000-1836 分机211 / 810 或拨0转总机

上海:021-54248686 分机 或拨0转总机

上海:021-54248686 分机 或拨0转总机

传真北京:010-84852750/84854139

上海:021-64418200

上海:021-64418200

泰亚赛福作为众多知名品牌的合作伙伴,优惠的价格+完善的售后服务体系向您提供产品。font>

品牌简介

Scientific-Production中心“Кropus”是拥有十多个子公司的无损检测技术的研发及生产设备的企业。Kropus公司成立于1989年,员工多数来自Pribor。有超过30年的行业经验,在应…Scientific-Production中心“Кropus”是拥有十多个子公司的无损检测技术的研发及生产设备的企业。Kropus公司成立于1989年,员工多数来自Pribor。有超过30年的行业经验,在应用无损检测及技术诊断方法上结合现代电子和无线电信号分析与处理,建立了一个范围广泛的现代设施超声波、涡流磁场。Kropus认可俄罗斯Gosstandart计量实验室,允许“Kropus”使用他们的方法来测量。

您最近浏览的商品

俄罗斯Кropus

俄罗斯Кropus